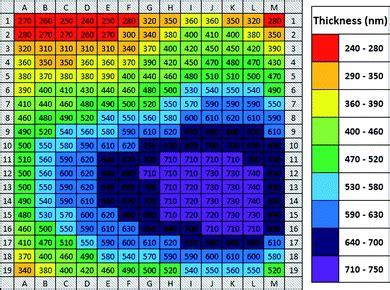

how to measure oxide layer thickness|thermal oxide color chart : Brand Oxide layers are transparent films. If light is irradiated onto the wafer and reflected, various properties of the light wave are changed which can be detected with metering devices. . To monitor the film thickness across the wafer, several measuring points are quantified (e.g. 5 points on 150 mm, 9 points on 200 mm, 13 on 300 mm wafers .

WEB2 dias atrás · Assistir Filmes online, Filmes 1080p, Filmes 720p, Assistir Filmes grátis, Assistir Filmes Online Grátis.

{plog:ftitle_list}

Experimente slot Book of Spells online e gratuitamente no modo demo sem download ou registo necessários.

Rutherford backscattering (RBS) is an excellent technique for determining oxide thickness over a wide thickness range by channeling the .An equivalent oxide thickness usually given in nanometers (nm) is the thickness of silicon oxide film that provides the same electrical performance as that of a high-κ material being used.. The term is often used when describing field effect transistors, which rely on an electrically insulating pad of material between a gate and a doped semiconducting region.

Electromagnetic acoustic resonance of 2.25 Cr–1Mo steel plates with (Fe, Cr)3O4 oxide layers of thickness from 0.03 mm to 0.18 mm were investigated. Due to the phase shift at the interface between the metal and the oxide layer, the resonance frequency, f n, was not proportional to resonance order, n, but n/f n varied depending both on the frequency and the oxide layer .– oxide d thick consumes a layer 0.44d thick of Si 0.44d d SiO 2 original silicon surface • “bare” silicon in air is “always” covered with about 15-20 Å of oxide, upper limit of ~ 40 Å – it is possible to prepare a hydrogen terminated Si surface to retard this “native” oxide formation

The thickness of a grown oxide layer, which is naturally formed on the surface of a metal, is measured using PHE-103 spectroscopic ellipsometer. A polishing process is performed to each metal before measuring the thickness of the grown oxide layer with time. It is found that the formed layers grow up faster after polishing and the rate of .Oxide layers are transparent films. If light is irradiated onto the wafer and reflected, various properties of the light wave are changed which can be detected with metering devices. . To monitor the film thickness across the wafer, several measuring points are quantified (e.g. 5 points on 150 mm, 9 points on 200 mm, 13 on 300 mm wafers .

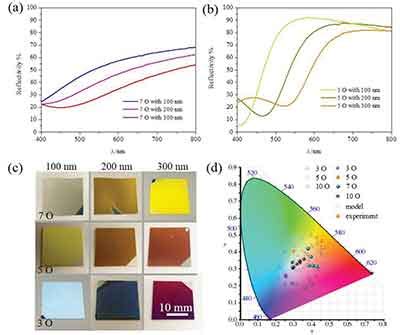

To measure the thickness (d) of a thin film, the complex refractive indices and incident angles should be known in advance.The total reflectance at each wavelength according to d can be calculated using such information. As a result, the thin-film thickness d can be determined as a specific value which makes the modeled total reflectance spectrum most .In thermal oxidation with silicon, the silicon reacts with oxygen to form silicon dioxide. The ratio of the grown oxide layer and of used up silicon is 2.27, which means that the dioxide is growing into the silicon substrate by 45 % of the total thickness .

As one of the reference measurement methods for future realization of the unit of mass (kilogram) and Avogadro constant N A, the silicon (Si) sphere method employs the ellipsometry for the measurement of the thickness of the ultrathin (<10 nm) silicon oxide layer (OL) with high accuracy. Depending on the reference standard used, the application of .

Thermal growth of aluminum oxide on the metal surface at low temperatures, i.e., below about 600 K [8], is generally self-limiting in the sense that the oxide thickness grows relatively fast to a .160 Chapter 5 MOS Capacitor n = N cexp[(E c – E F)/kT] would be a meaninglessly small number such as 10–60 cm–3. Therefore, the position of E F in SiO 2 is immaterial. The applied voltage at the flat-band condition, called V fb, the flat-band voltage, is the difference between the Fermi levels at the two terminals. (5.1.1) ψg and ψs are the gate work function and the . I have a sample of a metal (aluminum/oxide) layer with a gradual thickness ranging from monolayer to 100nm. This layer is deposited on a transparent substrate, like glass. How can I measure this thickness variation across the sample, qualitatively or quantitatively? Film thickness ranges from 0 to several nms.sure of the passivation thickness is the intersection of the iron and oxygen traces in Fig. 3-5. The mechanically polished surface has an oxide layer that is approximately 2 nm thick. The 30 minute passivation treatment yields an oxide layer that is about 19 nm thick; the 60 minute treatment produces a 50 nm oxide layer. Figure 6 shows the

A polishing process is performed to each metal before measuring the thickness of the grown oxide layer with time. It is found that the formed layers grow up faster after polishing and the rate of growth decreases with time. In a period of 144 h, the oxide layer formed on zinc is about three times that formed on cadmium.

general tools pin pad moisture meter

thermal oxide color chart

The oxide layer in a semiconductor device is a very efficient electrically insulating layer on the surface of a material. This oxide layer serves as a dielectric in numerous devices. 2 Moreover, the oxide layer is a favored masking layer in many steps during device fabrication. 1,2 The oxide growth rate and therefore its thickness X 0unpassivated sample. However, the chromium oxide thickness is also reduced on the passivated sample. This reduction in total oxide thickness means that more of the iron-rich metallic substrate is seen by the surface XPS measurement. Figure 4: Sputter depth profiles of unpassivated and passivated steel surfaces Summary

Conversely, if oxide thickness is constant, a change in substrate doping causes a corresponding change in depletion layer capacitance. This is easy to understand because increasing (or decreasing) substrate doping causes the maximum width of the depletion layer to be reduced (or increased). Therefore, for a specified oxide thickness, C ox The buildup and thickness of the oxide layer depends on the humidity of the air or the composition of the water. The oxide layer does not offer protection against corrosion in all cases. Oxide layers and protective effects can be strengthened by the action of boiling water or steam. A surface layer of aluminum monohydrate (boehmite) of one- to .Commercial iron particles have a thin oxide layer that serves three roles: (i) to prevent sintering during particle preparation, (ii) to modify the magnetic properties, and (iii) to passivate the iron surface. The thickness of the oxide layer is about 4 nm (Rosler et al. 1996).

We would like to show you a description here but the site won’t allow us.

A method has been developed for measuring the thickness of submonolayer native oxides formed on silicon wafers during rinsing. The method utilizes a rapid acid-etching process developed in our .Integrity NDT Solution – To determining the oxide layer thickness, Integrity NDT are using a high frequency delay line ultrasonic probe typically (Single crystal delay line compression wave probe 20MHz 0.125mm), and broadband digital UT flaw detector. The flaw detector must be capable of detecting echoes and measuring the short time interval between the peaks, .Another way to measure the thickness of an oxide coating is to use chronopotentiometry. Basically, you apply a cathodic current to the oxide and you determine the time required for the reduction .

The chromium present in stainless steel reacts with oxygen to form a thin, inert oxide layer over the entire surface that provides corrosion resistance, and regenerates itself when damaged. . Measuring the thickness of coatings applied to stainless steel substrates can be difficult for conventional handheld inspection instruments, depending . Here are some common problems and ways to measure coating thickness. Advertisement The Voice of the Finishing Industry Since 1936 Subscribe Electroplating . it is difficult to measure layers that are composed of numerous elements, like metal oxide layers, or multilayered deposits consisting of the same element, like a semi-bright and bright .

Measurement of film thickness can be done with many different instruments. Understanding the equipment that is available for paint thickness measurement and how to use it is useful to every coating operation. . In some circumstances, individual layers in a multi-layer system can be measured. Typical tolerance for this device is ±3%. Standard .

Passive film contains a chromium-rich inner oxide layer and an iron-chromium hydroxide outer layer with an amorphous stucture 18,19,20,21,22,23,24,25. Recently, nanocrystals were also found in the .The thickness and properties of the oxide layer on Al (aluminium) also depends on the environment. It is typically said there is a passive Al oxide layer. . Ways of measuring thin film thickness .

silicon nitride thickness color chart

general tools pin pinless moisture meter for water damage

5 dias atrás · Глава общественного движения «Мы вместе с Россией » Владимир Рогов назвал идею главы министерства .

how to measure oxide layer thickness|thermal oxide color chart